I drove north from Colonia during a heavy storm. When I arrived in the early afternoon, Fray Bentos was deserted. It looks like it has seen better times. Once the weather improved it did get some life back into it.

Advance Warning: This is a very technical post probably only of interest to those interested in agricultural/industrial history.

I came here to visit the Museum of the Industrial Revolution UNESCO world heritage site, aka the old Fray Bentos factory. (www.welcomeuruguay.com/../industrial-revolution-museum)

The town was chosen by Societé de Fray Bentos Giebert & Cie as the location for a factory to make “Liebig’s Extract of Meat” using Justus Von Liebig’s process. The region was already a big cattle producer but was only growing them to export the hides with minimal meat exports due to the lack of preservation techniques. Much of the meat was going to waste.

After a successful two year test phase, the main factory started production in 1865 on the banks of Rio de la Plata.

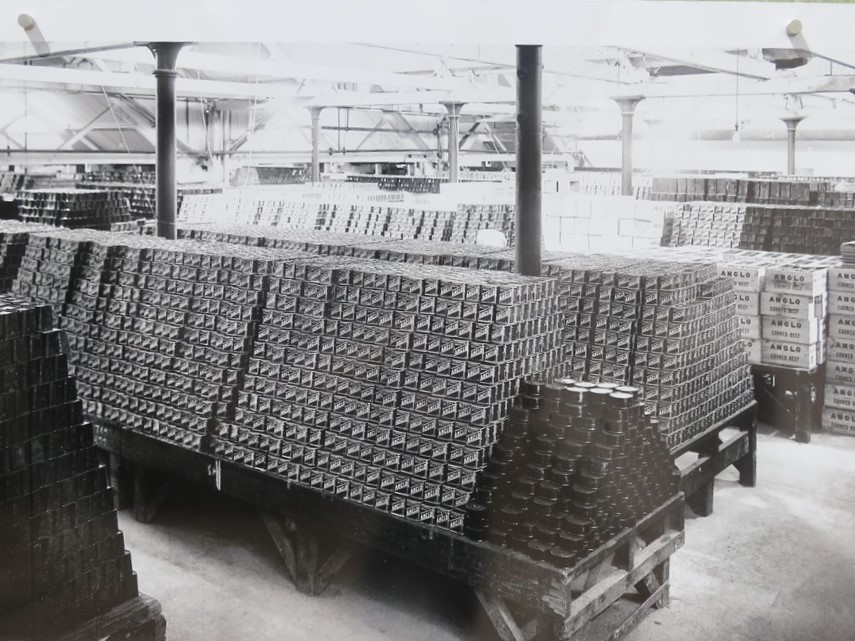

At it’s peak, the factory employed 5,000 staff (1930’s) and built its own town to house the workers. By 1875, it was producing 500 metric tonnes of the product per year. It started introducing new products, including the introduction of Fray Bentos Corned Beef in 1873 and OXO cubes in 1911.

The company was managed by German staff locally, who had significant share holdings, but was mainly funded by British investment. This arrangement lead to it supplying both sides during World War I.

After the end of World War I, demand for their products fell and the company fell on hard times. It was acquired in 1924 and became Frigorífico Anglo del Uruguay, a solely British company. This gave its name to the town that has built up around the factory – Barrio Anglo.

The new company invested heavily in the new ammonia based refrigeration technology. This, and the introduction of steam ships which could run refrigeration units on board, meant that the company was able to start exporting beef.

Production of the original products continued and over 2 million tins of corned beef were shipped to the US army during the second world war. It didn’t supply the German army this time.

Further products were added and at one point the product range ran to several hundred items.

What is left of the factory is the infrastructure used from 1924 onwards. The machine room still has the generators and ammonia pumps used to run the massive refrigeration unit.

The massive refrigeration unit was 100m by 40m and 5 floors high. The top 2 floors were used to keep fresh meat chilled before it was put on ships. The bottom 3 floors were used to freeze meat for future use in the traditional products. Using very early refrigeration techniques, the ammonia atmosphere in the freezers was so strong that staff were only allowed to work in there for 20 minutes before taking at least a 30 minute break.

The slaughter house is also huge and could slaughter up to 1,800 animals in a 24 hour period. It was only in use for one or two days per month and mainly operated during the night shift when temperatures were cooler. Staff working in the slaughter house were the highest paid on the site and also had bigger meat allowances and better access to the company hospital.

The processing plant for the original meat extract is still intact.

One of the compressors in that plant room had a rather familiar name on it.

The factory consisted of 36 different buildings.

Many of the walkways are made of plate steel. This is because the early sailing ships used it as ballast on their outward trip from Europe and then dumped it once loaded with meat products. Later on, ships used coal as ballast on their outward trips. This was then used in the boilers that powered the machine room all other plant in the factory.

The river has already reclaimed much of the piers that were used for loading ships.

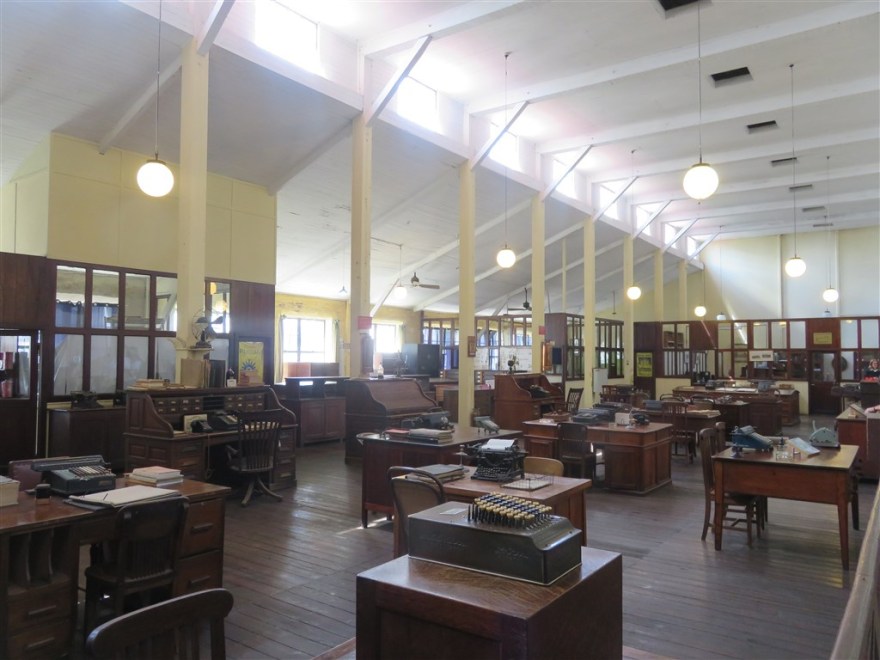

The factory office is best preserved part of the factory. The Anglo company continued until they decided to shut the factory in 1968 due to falling demand and increased competition. During the period from 1924 to 1968 the factory became self sufficient in its requirements for maintaining the 1920’s equipment. This was mainly due to their remote location and the cost of importing spare parts. They used every part of the animals slaughtered at the plant and even used animal hair to make their own paint brushes.

When Anglo announced the closure of the plant in 1968, the Uruguay government stepped in and bought the plant as it stood and significant amounts of surrounding land for US$1,000,000. The only thing they didn’t buy was the Fray Bentos brand name. This has since been sold on several times and is currently owned by Baxter’s Soup in Scotland. The Government continued to run the factory until 1979 when it admitted defeat and finally closed down the business. At the same time it declared the site a national monument/museum which ensured everything was moth balled. The office was continued to administer the museum until it was made a UNESCO world heritage site in 2015.

There are two particular items of interest in the office. The first is one of the very first type writers which dates back to 1903. Rather than use the better know keyboard, this early model required the user to point to the letter required and then press either a capital or lower case button to print the letter.

The other is the first ever light bulb used in the plant which dates back to 1883. At this time the factory was very technologically advanced and used electricity 4 years before it became available in Montevideo. The generators used at that time were much smaller than those seen in the 1920’s machine room. However, they supplied lighting for all of the plant and powered some machines. In the evenings, when less power was required, output was diverted for use in the factory houses.

The general manager’s house is also part of the museum but only available to tour on Thursday mornings. I visited on a Wednesday.

Although UNESCO provide the prestige and the publicity of world heritage site status, they don provide any funding. The site trustees have looked for other sources of income and recently some of the unused buildings have been converted into a campus for the Technical University of Uruguay – UTEC.

The surrounding land is used as common park land. Many of the locals keep their horses there.

They have also built a race track.

It also has some nice beaches.

After Fray Bentos, I had originally intended to drive north to Salto. There I planned to visit the hot springs and hydro electric plant. Upon advice from my work colleagues in Buenos Aires, I decided to head south to the beach resort of Punta del Este instead. This gave me an excuse to splash out on a fancy hotel for a couple of nights.